Rip & impact resistance standards and test methods

Rip, tear and impact resistance – quality standards

Although not a cover grade or carcass classification in its own right, the ability of a conveyor belt to withstand the impact of heavy, sharp objects falling from height and the forces that rip and tear them is often more important than any other physical attribute. Even the strongest, heaviest belts can be punctured and ripped by foreign objects and sharp rocks becoming trapped. A ‘rip’ is what happens when a sharp object punctures the belt and cuts the belt longitudinally as it is pulled against the trapped object. In contrast, a ‘tear’ is what happens when a section of belt is pulled apart in opposing directions; very much like tearing a piece of paper in two. There are currently no ISO quality standards for rip, tear or impact resistance relating to actual performance. However, every belt carcass and every rubber cover compound that we produce undergoes strenuous laboratory testing requiring the consistent achievement of very demanding Dunlop quality performance standards.

Rip resistance – test methods for rubber covers

No international test methods for evaluating the rip resistance of rubber covers exist.

Rip resistance – carcass test methods

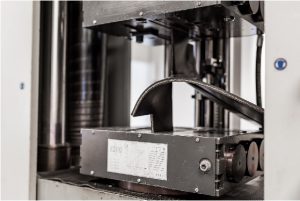

As with the rubber covers, there are no internationally approved methods for testing the rip resistance of the carcass. However, at Dunlop our research & development laboratory engineers use a highly effective test using specially designed equipment whereby sections of belt are pulled through a right-angled piece of metal. The laboratory technicians have nicknamed the equipment ‘Jack the Ripper’. They also regularly carry out this test on samples of belting produced by other manufacturers so that we can be sure that our belts continue to set the benchmark for rip resistance.

Photo: Dunlop’s ‘Jack the Ripper’ rip test in action

Tear resistance – test methods for rubber covers

The ISO 34-2: 2015 test method is used to measure the resistance of rubber belt covers to tearing. Testing is performed by pulling specimens of rubber apart using a universal test machine equipped with tensile testing grips.

Tear resistance – carcass test methods

There is a different test method for measuring the tear strength of the actual belt carcass. ISO 505:2017 measures the propagation resistance of an initial tear in textile conveyor belts, either in full thickness or of the carcass only. This test is intended for application to textile belts in installations where there is a risk of longitudinal tearing. Although it is a defined method of testing there are no standardised performance requirements. The test basically consists of mounting two cut ends of a test piece of belting in the jaws of a tensile testing machine. An initial tear is made in a test piece, which is then pulled apart in opposing directions, which is why it is often referred to as ‘the trouser test’. The force necessary to propagate the tear is then measured. Examination and analysis of the multi-peak tear resistance test traces is made in accordance with ISO 6133.

Photo: ISO 505 carcass tear testing