Conveyor belts – calculating their true cost.

No matter what price you pay, it is the reliability and longevity of your conveyor belts that actually determines their true cost. Buying a conveyor belt because it is more ‘competitively priced’ rather than a premium quality one that will require a much lower level of intervention (running repairs and unplanned maintenance) and ultimately provides a much longer operational lifetime simply does not make economic sense.

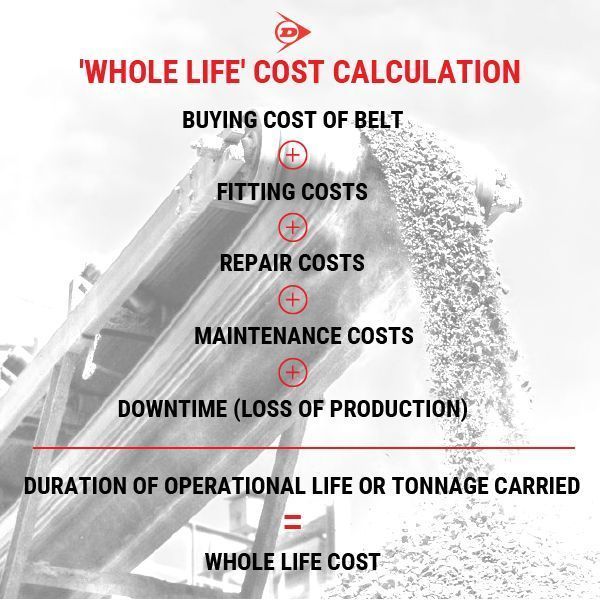

To calculate the true cost of a vitally important and complex component such as a conveyer belt, it is essential to include all other directly related costs on top of the ‘above the line’ price that you pay for the belt itself.

Calculating ‘whole life cost’.

The principal of ‘whole life cost’ calculation is simply to add the cost (excluding VAT) of the conveyor belt to the cost of its installation including splicing. Once installed and running, below the line’ costs such as the labour and material costs incurred repairing the belt (including splice repairs) during its lifetime plus the estimated costs of the output lost to stoppages while those running repairs were carried out need to be calculated. Add to this the cost of the removal and replacement of the belt when it needs to be replaced, again including the cost of downtime. And in the event of a sudden catastrophic belt failure and no replacement belt on site, the costs start to rocket even higher over much-extended periods.

The final step is to divide the total of these costs by the period of time that the belt has run or, if known, the amount of material conveyed during that lifetime. On conveyors that are usually running non-stop during the day then time is usually the best measure. However, if the conveyor operates intermittently then using tonnage as the basis for the calculation usually proves to be more accurate.

Not all conveyor belts are created equal.

As with the selling price, there are frequently huge differences between the performance and longevity of one conveyor belt and another, even when they both claim to meet the same specifications and international standards of quality. Especially in recent years, these differences have been magnified by the tidal wave of low-grade ‘sacrificial’ conveyor belt being imported from Southeast Asia, primarily China.

Nowadays, it is increasingly common to see good quality European-made belts provide up to four or five times longer operational life. For example, to quote one operations manager in Scotland, “We used to replace our belts every three to six months. Now it can be four or five years before we need to fit a replacement”. The high-grade belts he refers to would certainly have an appreciably higher price tag, but it is extremely unlikely to have been three or four times higher. Building in the cost of more frequent change-outs and the other associated below the line costs means that the seemingly unbeatable low price becomes, in reality, hugely more expensive.

Dramatic difference.

The dramatic differences in both reliability and longevity are easy to explain. To make a good quality conveyor belt requires high quality materials and production values and these cost appreciably more than the poor quality alternatives. There are two very distinct kinds of conveyor belt manufacturer – those that produce belts with the objective of achieving high standards of performance and longevity and those who produce belts where the primary driver is to achieve a selling price that its competitors cannot possibly match.

The numerous methods used to achieve this include unregulated, low-grade raw materials including poor quality rubber and fabric plies; bulking agents such as chalk and clay; recycled scrap rubber of highly questionable origin; the substitution of essential polymers such as carbon black with low-grade versions and minimal quantities (and often the total omission of) key ingredients such as the antioxidants necessary to resist the premature rubber degradation caused by exposure to ozone and ultraviolet light.

Predicting the lifespan

The most challenging aspect of selecting conveyor belts based on whole life cost is that it can be difficult to predict the lifespan of a belt of a type or supplier that you may never have used before. As you would expect, suppliers of conveyor belts, regardless of their reputation for quality or otherwise, can never guarantee how long a belt will last. There are simply too many influencing factors. Do not let this put you off. If you choose a tried and trusted manufacturer, especially one actually manufacturing in Europe, then the gains are usually considerable. As the old saying goes, “If you never try something different then you will always get what you already have”.

Jeremy Clark.