Fenner Dunlop UsFlex®

Fenner Dunlop UsFlex®

THE ULTIMATE SOLUTION

HIGH IMPACT, TEAR AND RIP RESISTANT BELTING

Key features of Fenner Dunlop UsFlex

Unrivaled impact,

rip and tear resistance

Longitudinal rip resistance that is more than five times stronger than multi-ply belts.

Excellent

load support

Excellent in mining, quarry, wood, paper and pulp, recycling, road construction, steel and transshipment industries.

Outstanding

troughability

The UsFlex carcass is based on the straight-warp principal.

THE ULTIMATE SOLUTION

In some applications, especially primary and secondary crushers, even the strongest and heaviest conventional belts can be ripped or torn by large lumps of heavy, sharp objects, either falling from a height or becoming trapped. Belts can often be destroyed within a matter of weeks or months. Our solution to this problem is UsFlex, which has longitudinal rip resistance more than five times that of multi-ply belts of equivalent rating because of our unique straight-warp construction. UsFlex provides impact resistance up to three times greater than that of conventional plied belting. This unequaled toughness means the belt will not be easily damaged in the loading and conveying of large, sharp material. As a result, UsFlex will provide the longest belt life in the harshest conditions!

Perfect for the following industries:

- Cement

- Mining

- Power generation

- Quarry

- Recycling

- Steel

- Transshipment

- Wood

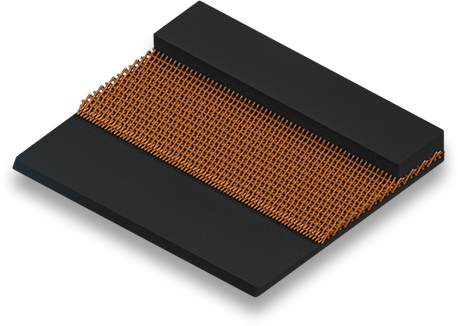

UsFlex Cross Section

Belt characteristics

UsFlex owes its outstanding impact and tear resistant characteristics to an innovative woven straight-warp carcass that is unique to Dunlop. This consists of heavy strands of polyester running lengthwise and heavy nylon strands running crosswise held in position by a strong yarn. The strands are completely straight in both directions and not interlocked as in a conventional belt carcass. This allows the weft to float free from the warp, thereby minimising the peak point of impact because the energy is absorbed over a larger area, providing maximum protection to the carcass.

Suitable for use in all areas, especially in high impact conditions and low maintenance environments including the mining, quarry, wood, paper and pulp, recycling, road construction, steel and transshipment industries.

Fenner Dunlop UsFlex is available from stock in two tensile strengths; 630/1 6+3 and 1000/2 8+3 in widths up to 2000mm. UsFlex belts are supplied with the abrasion resistant ‘RS’ cover as standard. The Fenner Dunlop RS cover grade exceeds the very highest DIN and ISO grades (DIN W and ISO 14890 ‘D ‘). Other tensile strengths and cover qualities can be made to or

The UsFlex carcass is based on the straight-warp principal and can be supplied in either single ply or two-ply versions.

Rip, Impact

& Tear testing

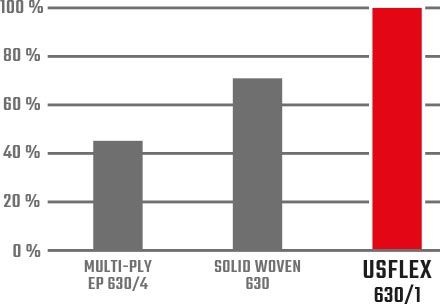

RIP RESISTANCE

The ‘secret’ behind the amazing rip resistant characteristics of UsFlex is the use of a unique and innovative ‘straight-warp’ woven fabric ply. This consists of heavy strands of polyester running lengthwise and nylon running crosswise. The strands are completely straight in both directions and not interlocked as in a conventional belt carcass. This allows the weft to float free from the warp. This means that if a sharp object penetrates the carcass the nylon crosswise strands have the strength and ‘freedom’ to compact (gather) together, effectively forming an increasingly stronger barrier. It is a broadly similar principle to that of a fabric rip-stop breaker ply but significantly stronger and more effective.

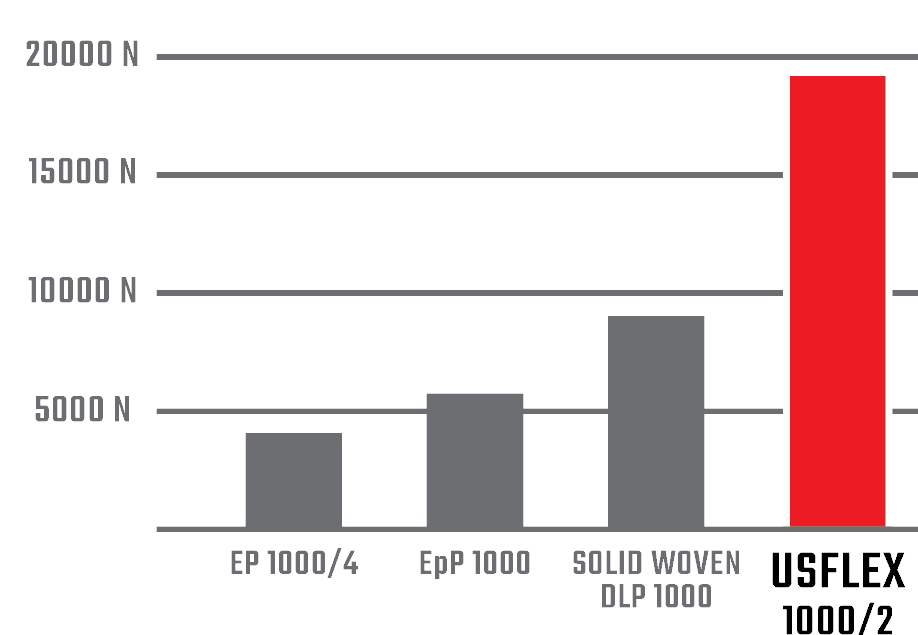

IMPACT RESISTANCE

Compared to conventional multi-ply and solid woven belting, the impact resistance of UsFlex is proven to be significantly superior. This is because the unique UsFlex design minimises the peak point of impact and absorbs (dissipates) the energy over a larger area compared to a conventional high tensile EP or EPP belt. For example, a single-ply UsFlex type 630/1 has the impact absorbing qualities of a 4-ply EP belt type 1600/4 or an EPP 1250/2. The chart shows the results of impact tests on 630 rated UsFlex, Solid woven and multiply belting.

TEAR RESISTANCE Testing

The tear resistance of UsFlex, measured according to the international EN ISO 505 standard, also significantly exceeds that of conventional multi-ply belts with comparable tensile strength. Tests for rip and tear resistance are only made on the actual belt carcass so the top and bottom covers are always removed. This ensures that the thickness and quality of the cover do not influence the accuracy and consistency of the tests.

What they say about the product

"We used to replace our belts every three to six months before we started fitting UsFlex belts. Now it can be four or five years before we need to fit a replacement. UsFlex really is an amazing belt"

THE BEST PROBLEM-SOLVING BELT

THAT MONEY CAN BUY

Finger splice