Eagle Eye®

ADVANCED STEELCORD BELT MONITORING TECHNOLOGY

Eagle Eye is the most advanced state of the art steel cord condition monitoring and rip detection system available on the market. While the system provides proven 24/7 protection through seamless integration with the conveyor control, it also allows users fast and easy access to information about the conveyor belt’s current condition. Eagle Eye Advanced also provides the extraction of historical data to enable future maintenance and replacement predictions.

Download area

Eagle Eye® advanced – for steelcord belting

FEATURES & BENEFITS

✓ 24/7 protection with steel cord condition monitoring, splice analysis and rip detection.

✓ Eagle Eye can position the belt at specified locations in order to conduct general inspections including splice joints, carry out repairs or for planned maintenance.

✓ Advanced real-time belt graphics with the ability to select multiple viewpoints and zoom levels.

✓ Multiple rip detection locations can be added to create up to four monitoring stations.

✓ Remote connectivity to other devices such as smartphones, tablets and control room computers.

✓ New multi-core processing that can link technical belt data with an intuitive interface for simplified user interaction and experience.

✓ Historical data collection for complete belt life analysis.

✓ Automatic reporting, extensive smart log messages and information filters.

✓ User-defined email and text message facility.

✓ Superior internal diagnostics for ease of system maintenance.

✓ Proven Allen Bradley PLC processing for reliable conveyor protection and ease of conveyor control integration.

✓ Custom engineered product to conveyor specifications manufactured in the USA at a certified Rockwell/Fenner Dunlop Facility.

COMPONENTS

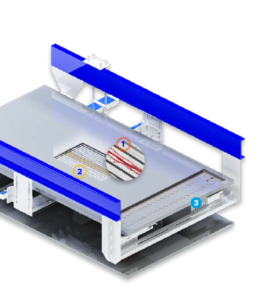

Steel Cord Condition Monitoring Array with precise Encoder feedback, Magnetic Array, RF Sensors to analyse Inductive Loops embedded at set distances in the belting.

APPLICATIONS

Any conveyor using Steelcord belting.

HOW IT WORKS

The system collects data from multiple sensors 1 to build a detailed map of events. Once the map of data is complete it continuously monitors each splice and steel cord damage 2 events for real-time changes and trends the data so the user is able to forecast potential issues through an intuitive interface. The system also continuously monitors Inductive loops 3 at up to four points to ensure belting continuity and minimize risk.

INTELLIGENCE AT YOUR FINGERTIPS

Eagle Eye Advanced makes it extremely easy to identify unexpected or developing belting problems quickly and pinpoint the failure area with precision. Also, next-generation internal diagnostics continuously monitors system hardware health and generates interactive troubleshooting steps to diagnose and resolve if a problem should occur.

New Interface

The new interface allows for additional processing power which enables Eagle Eye Advanced to collect, store and analyze historical data, and then provide improved performance trends as to how something might fail, helping you to have a more comprehensive understanding of the belt life. In addition, our new system offers increased connectivity, which can be accessed from any smart device including emails and a new texting feature. Supporting access from mobile devices!