Fenner Dunlop Ultra X®

Fenner Dunlop Ultra X®

THE ULTIMATE SOLUTION

THE NEW ECONOMIC SOLUTION TO A WIDE RANGE OF EXPENSIVE PROBLEMS!

Key features of Fenner Dunlop Ultra X

Longer Life

We solved the problem of rapid wear caused by abrasion many years ago. Fenner “Made in Holland” belts are well recognized as the longest lasting belts

Unique Technology

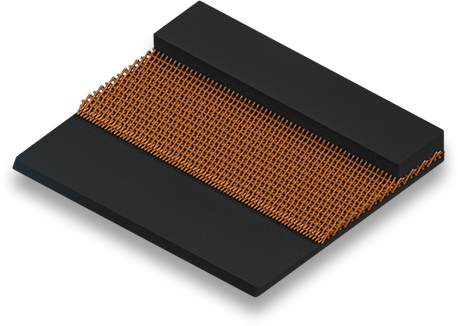

Ultra X is a super-strength abrasion resistant ‘breaker weft construction’ single-ply belt that is exclusively made by Fenner Dunlop Conveyor Belting

Superior Splice Strength

Ultra X is best joined using the finger splice method. This creates the strongest and most reliable joint possible by retaining up to 90% strength

SUPER-TOUGH, SUPERB ECONOMY

Even the strongest, heaviest belts can be ripped, torn or punctured by heavy, sharp materials or foreign objects, either falling from a height or becoming trapped. Belts can often be destroyed within a matter of weeks or months. The Fenner Dunlop solution to this very old problem is a new and unique belt design – Fenner Dunlop Ultra X.

Ultra X is a super-strength abrasion resistant 'breaker weft construction' exclusively made by Fenner Dunlop Conveyor Belting. It has outstanding impact resistance and up to three times the rip resistance and five times the resistance to tearing compared to conventional multi-ply belting of the equivalent tensile strength. Despite its numerous physical and technical advantages, Ultra X is also exceptionally economical in every respect.

Perfect for the following industries:

- Cement

- Chemicals & Fertilizers

- Mining

- Power generation

- Quarry

- Recycling

- Steel

- Sugar & Food

- Transshipment

ADVANTAGES COMPARED TO MULTI-PLY BELTING

- Far Superior Impact Resistance

- At Least 30% greater Splice Joint Strength

- Excellent Mechanical Fastener Retention

- Can Be Used on Smaller Than Usual Pulleys

- Low Elongation, Compared to ‘normal’ Plied Belting

- Short Take-up Travel Good Troughability

- Good Running Behaviour

Ultra X1 is designed as a stronger alternative to 250/2, 315/2 and 400/3 abrasion resistant multi-ply belts. Ultra X3 is designed as a stronger alternative to 500/3, 500/4, 630/3 and 630/4 abrasion resistant multi-ply belts.

In order to provide the most economical prices as possible, Ultra X is only available in full rolls of 300m or alternatively of 2 X 150m rolls if necessary.

The minimum order for each type is 600 square meters (300m X 2000mm) cut in any combination of

the following widths:

Ultra X1: 500mm , 650mm, 800mm, 1000mm, 1200mm, 1600mm or 2000mm.

Ultra X3: 500mm, 800mm, 1000mm, 1200mm, 1600mm and 2000mm.

Ultra X is a super strength abrasion resistant breaker weft construction single-ply belt that is exclusively made by Dunlop Conveyor Belting including the patented super-tough fabric, which is made in our in-house fabric weaving facility. Ultra X is designed to be a much stronger, more durable alternative to conventional multi-ply belting.

What our customers say

"Ultra X is very resistant to cutting and tearing. We are placing this belt in very demanding workplaces and the results are very good. It avoids a lot of repairs and breakdowns. "

Splice Strength

Ultra X is best joined using the finger splice method. This creates the strongest and most reliable joint possible by retaining up to 90% of tensile strength. This is because the step splice will always create a proportional ‘loss’ of tensile strength that is the equivalent of one ply.

| Number of plies | Maximum % Tensile Strength |

|---|---|

| 2 | 50% |

| 3 | 66% |

| 4 | 75% |

| 5 | 80% |

Tear Resistance Testing

The tear resistance of Ultra X measured according to the international EN ISO 505 standard significantly exceeds that of conventional multiply belts. Tests for rip and tear resistance are only made on the actual belt carcass so the top and bottom covers are always removed. This ensures that the thickness and quality of the cover do not influence the accuracy and consistency of the tests.

Fenner Dunlop Ultra X

The most economic solution

- Longer wear life (up to 20% superior to DIN Y)

- Reduced frequency of belt replacements

- More robust carcass - fewer repairs

- Lower maintenance

- Finger splicing = fewer splice joint renewals