Ultra X3

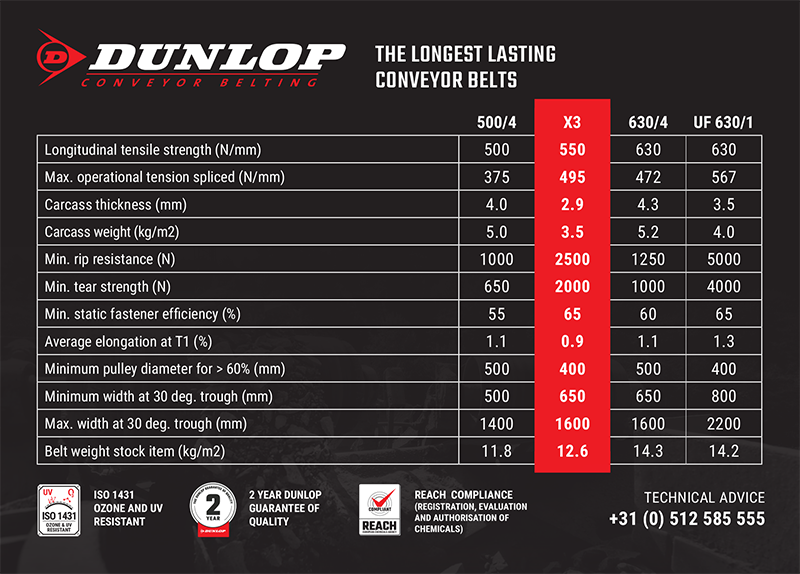

The cement plant operators had been experiencing regular problems in the splicing area of the main conveyor belt carrying materials to the bulk storage area and with rapid wear of the top cover because of aggressive materials and scrapers. Conventional 500/4 4+2 DIN Y belt was repeatedly failing at the splice joint and causing damage to the belt and skirts. This was causing frequent shutdowns and loss of production.

When a Dunlop Ultra X3 was fitted it immediately proved better suited to the drive pulley and tripper arrangement. The finger splice used on the Ultra X is much stronger and more reliable than conventional step splice joints. After 15 months of operation, the splice joint remains in excellent condition and the AA covers on the belt look far better than the previous multi-ply belt had done after only 10 months operation. The plant operator and their engineers are delighted with the excellent reliability, reduced downtime and much lower maintenance costs that the Ultra X belt has helped them to achieve.