CHOOSING THE RIGHT TYPE OF BELT EDGE CAN AVOID UNNECESSARY COST AND DELAY

When requesting a quotation for a conveyor belt, specifying the wrong type of belt edge can have an enormous impact on belt costs, repairs, maintenance and lost production. Despite the continual advances in technology and the types of materials used to manufacture rubber multi-ply conveyor belts, many conveyor technicians and conveyor belt buyers seem to retain outdated beliefs. Although there are only three basic types of belt edge, the importance of which type to use is often underrated.

Moulded edges – Many years ago, moulded edges were the standard because cotton was used as the reinforcing fabric in multi-ply belts. A moulded edge was therefore essential in preventing moisture penetrating the cotton fabric and causing it to rot. However, since the introduction of synthetic ply fabrics using polyester and polyamide, this problem effectively no longer exists.

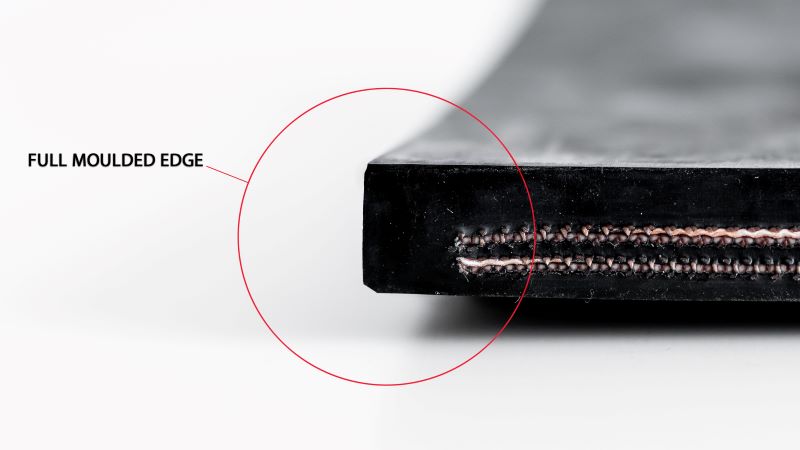

Full moulded edge

Moulded edges can only be created when a belt is manufactured to an exact width. During the calendaring of the belt, a small strip of unreinforced rubber is attached to the side of the carcass. This becomes an integral part of the belt during the vulcanizing process, creating between 5mm to 15 mm of unreinforced rubber on the belt edge. Moulded edges do not provide any structural advantage and can be susceptible to damage if the belt wanders off-track for any reason.

Sealed edges – The most often used type of belt edge is the ‘cut & sealed edge’ or simply ‘sealed edge’. The majority of rubber multi-ply belting is held in stock by manufacturers, distributors and traders in the fastest moving widths. To maximise the efficiency of production and minimise cost and environmental impact, these standard-width stock belts are usually made as wide as the manufacturing machinery will allow. These are known as ‘slabs’, which are then cut and sealed to create a variety of narrower widths. For example. 400 meters of 2200mm wide belt would be manufactured and then be slit (cut) to produce 400m of 1000mm wide belt and 400m of 1200mm wide.

Sealed edge

At Dunlop, the sealed edges are automatically created during the slitting process using special cutting knives that rotate at an extremely high speed. The heat created by the friction of the rotating knives melts the carcass fibres and a small amount of the rubber on the edge of the belt, effectively creating a seal.

Having a sealed edge means that moisture is prevented from being drawn into the carcass from the edge by capillary forces. Although the synthetic fibre plies are hardly affected, moisture can ultimately cause vulcanising problems when making splice joints. Having a sealed edge also enables a belt to be used in very wet conditions and makes it better suited to long-term storage outdoors. For these reasons, the use of unsealed (raw) cut belt edges, which are produced using conventional cutting knives, is not recommended.

Unsealed (raw) cut belt edge

Steelcord and steel reinforced belts – In the case of steelcord and steel reinforced ply belting, it is necessary to use moulded edges to prevent moisture penetrating the carcass and corroding the steel. In Dunlop, all steel cord belts are made to order and manufactured to a specific set of specifications that fully embed the steel cords so for these reasons they are always supplied with moulded edges. Multi-ply belts that are ‘made to order,’ usually those with specialised cover grades such as fire resistant for example, or simply in a non-standard width requested by the customer, will automatically have moulded edges.

Avoiding unnecessary cost and delay – Specifying moulded edges when they are not entirely necessary can have a very negative impact on the price because, as previously explained, manufacturers need to make belts at the optimum width for cost and environmental efficiency, while causing a belt to be made to order rather than supplied from stock also significantly increases the delivery lead time.

Les Williams